wire and cable

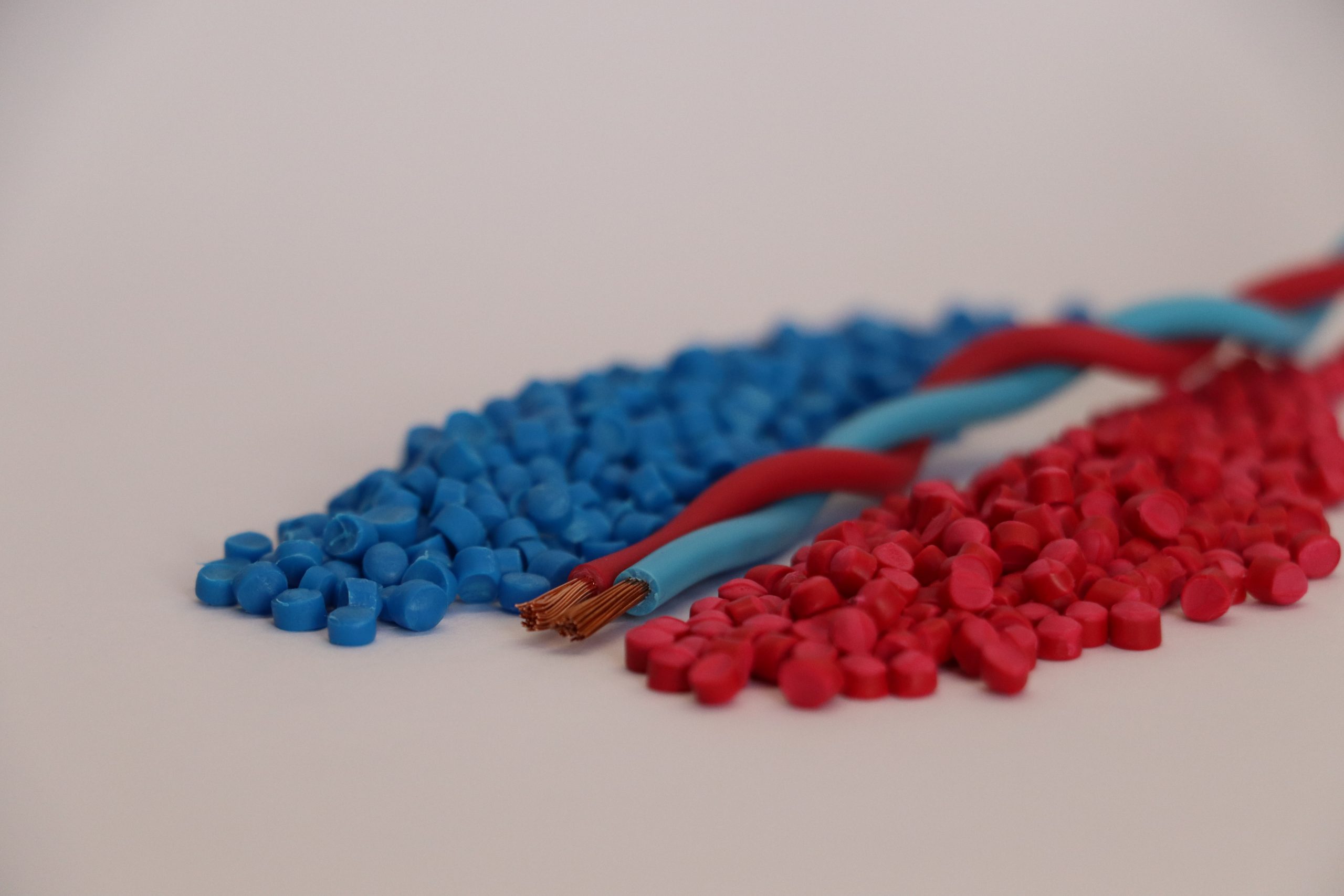

Cable coating and insulation :

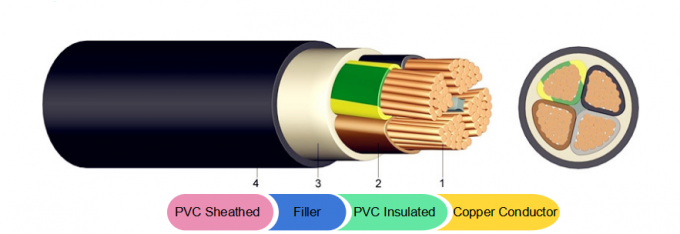

PVC is widely used for covering the cable in the structure of electric cables. In the 1950s, PVC gradually replaced rubber, which was used as a coating and insulation in household wires and cables. The cable made of affordable PVC has a very high durability and usually its lifespan reaches 25-30 years. Because its properties are easily modified, it is considered one of the most versatile thermoplastic materials. Although PVC is inherently rigid, it is easily modified with softeners, stabilizers, lubricants, and various other fillers. The cable with insulation or PVC sheath is flame retardant, which is important in most cases for electrical cables. PVC can withstand a wide range of chemicals including oil, acids and alkalis, the addition of various additives can increase its temperature range, typically from -40 to 105 degrees Celsius, as well as light resistance. Sun, reduce smoke emission and improve water resistance. Therefore, it is a suitable option for low and medium voltage cables. By producing a wide range of wire and cable industry compounds, Khoram Plastic Company has been able to make a great contribution to meet the needs of the country and also take a big step in the development of its export markets.

Introduction of 125CCZ grade PVC insulation

Compound based on calcium-zinc stabilizers, which is recommended in the production of insulating cables for use in extruders (L/D 22-24). This category of products is divided into 3 categories B, A and A+ based on price and specific weight, which can be obtained in the table below with the relevant properties and datasheets.

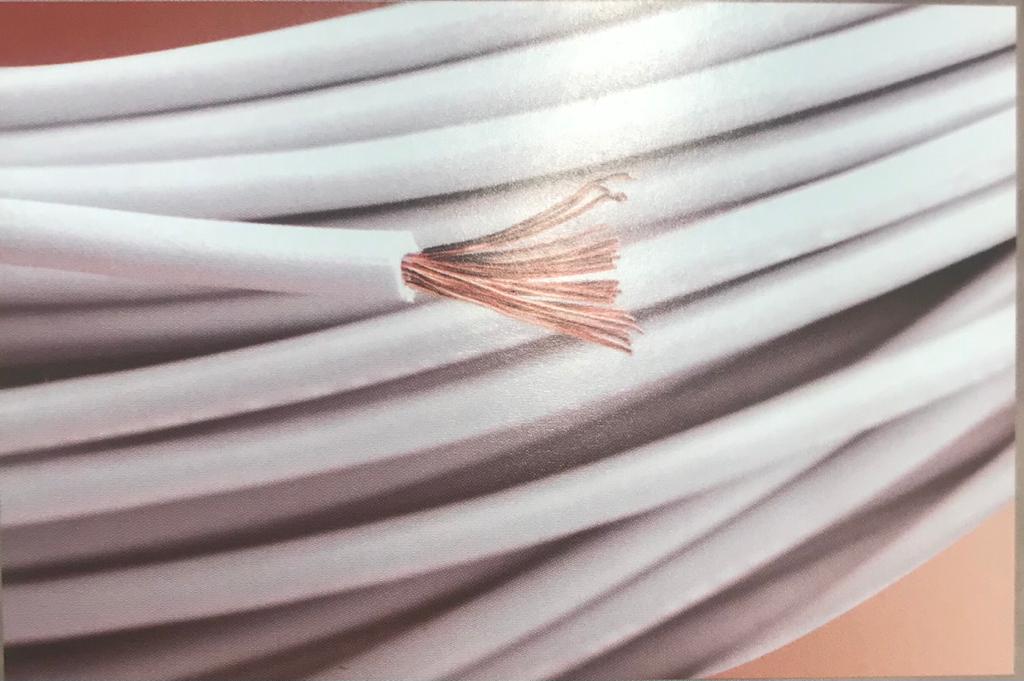

PVC insulation :

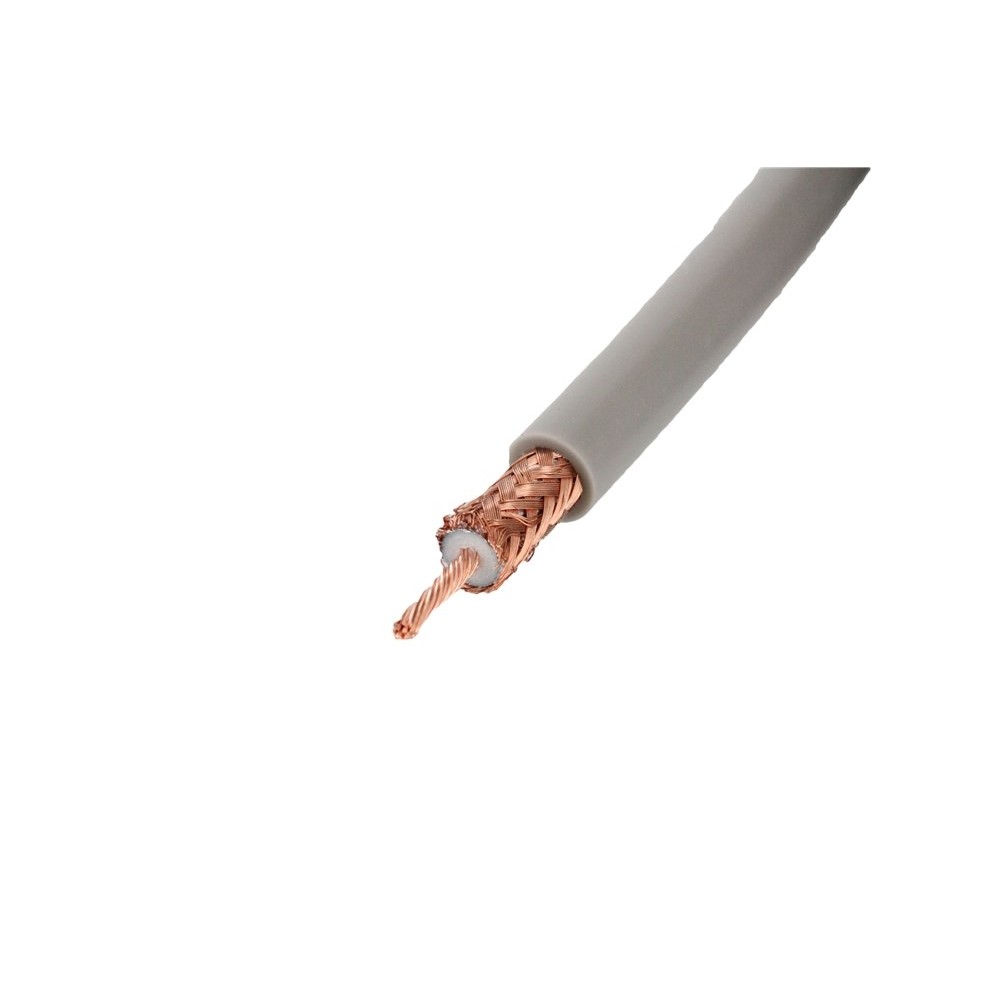

PVC coating :

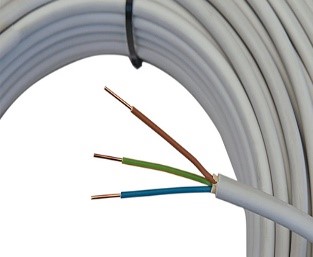

Filler :

Fillers are used to create a rounder and smoother structure to the cable and a cleaner effect and to fill the empty space inside the cable. Fillers will increase flexibility, protect the insulation or coating, and ease the production process. Fillers are often made of PVC.

Khorram Plastic Company of Tehran has been able to be one of the pioneers and the first producers of cable fillers in Iran by applying modern technology and knowledge and complying with existing standards in the field of filler production.