Wire and Cable

Wire and Cable

PVC remains one of the primary polymers used in the wire and cable industry due to its numerous technical and economic advantages. The key benefits of PVC include:

- Excellent electrical properties and reliable insulation performance across a wide temperature range

- Inherent fire safety resulting from the low flammability of PVC

- Flame-retardant behavior with limited flame propagation and moderate heat release

- High durability and long service life

- Ease of processing and fabrication

- Cost-effectiveness

- Recyclability

- Strong resistance to hydrocarbons such as oils and diesel fuels

- Good resistance to ultraviolet (UV) radiation

As of 2015, PVC accounted for approximately 50% of the global cable market, slightly surpassing polyethylene in overall usage within the cable industry.

Applications of PVC in the Cable Industry

PVC is widely used in the production of various cable types, including:

- Conventional low- and medium-voltage power cables for residential and commercial buildings

- Telephone cables

- Coaxial cables for television, computer, and Hi-Fi systems

- Automotive cables

- Data transmission cables, including LAN and IT cables

- Twin flat insulated wires (commonly known as white twin wires)

- Insulation and sheathing for antenna, telecommunication, and computer cables

- Welding cables

- Spray and flexible cables

- Cable fillers and bedding materials

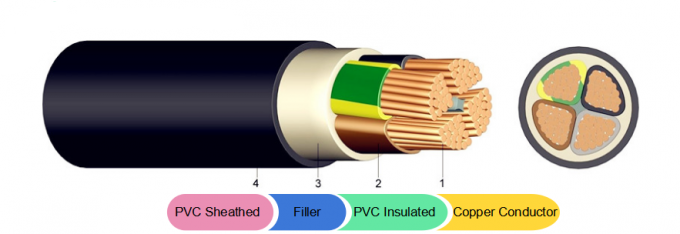

Cable Coating and Insulation

PVC is widely used as insulation and sheathing material in the structure of electrical cables. Since the 1950s, PVC has gradually replaced rubber, which was previously used as insulation and jacketing material in household wires and cables. Cables manufactured with cost-effective PVC offer high durability, with a typical service life of 25 to 30 years.Due to the ease with which its properties can be tailored, PVC is regarded as one of the most versatile thermoplastic materials. Although PVC is inherently rigid, it can be readily modified through the addition of plasticizers, stabilizers, lubricants, and various fillers to achieve the desired flexibility and performance characteristics.

Cables insulated or sheathed with PVC exhibit flame-retardant properties, which is a critical requirement in most electrical cable applications. PVC also demonstrates excellent resistance to a wide range of chemicals, including oils, acids, and alkalis. With the incorporation of appropriate additives, its operating temperature range can typically be extended from –40°C to +105°C, while also improving UV and light resistance, reducing smoke emission, and enhancing water resistance.For these reasons, PVC is an ideal material for low- and medium-voltage cable applications. By producing a wide range of specialized compounds for the wire and cable industry, Khoram Plastic Company has made a significant contribution to meeting domestic demand and has also taken major steps toward expanding its export markets.

PVC compound for plug production is formulated with Phosphite-Lead stabilizers and high-quality raw materials to deliver excellent performance in injection molding processes. It ensures smooth flow, precise shaping, and consistent thermal stability during processing. The specialized formulation produces end products with a glossy, smooth surface finish, high mechanical strength, and long-term durability. Controlled levels of stabilizers and lubricants help prevent discoloration or surface defects during molding. This compound is an ideal choice for manufacturing plugs, sockets, electrical fittings, and other high-quality molded PVC components.

Product Grade: Product Grade: |  Color: Color: |

|---|---|

| 130CBL 001 | Colorless |

The transparent PVC sheath for chandelier wire is made from high-quality soft PVC compound, designed to provide excellent transparency, flexibility, and thermal resistance. With its smooth and glossy finish, it enhances the visual appeal of chandelier wiring while maintaining resistance to light exposure, heat, abrasion, and discoloration over time. Its special formulation ensures easy processing, good adhesion to the conductor, and long-lasting softness under varying temperatures. This product is an ideal choice for chandelier wires, decorative lighting cables, and exposed indoor wiring that require both durability and aesthetic clarity.

Product Grade: Product Grade: |  Color: Color: |

|---|---|

| 129BT5 014 | Transparent |

The Automotive Welding Cable is made from durable and flexible PVC and is available in two grades to meet diverse automotive requirements. The PVC + TPE blend grade offers excellent flexibility, high thermal and mechanical resistance, and outstanding protection against abrasion and oils, making it ideal for welding cables and heavy-duty automotive applications. The economical pure PVC grade maintains standard quality at a competitive cost, providing a reliable solution for general and lighter automotive uses. Both grades are engineered for stable electrical performance, mechanical strength, and long service life, even under demanding conditions.

Product Grade: Product Grade: |  Color: Color: |

|---|---|

| 106CCZP2 001 | Black |

PVC Insulation

Grade A+ is designed to provide the highest gloss and superior mechanical properties while maintaining the lowest specific gravity among the available sheathing grades. This combination ensures both excellent visual appearance and robust performance in cable applications.

The product is rated for a service temperature of 70°C and a working voltage of 0.6/1 kV, making it suitable for standard flexible cable applications. In terms of international standards, Grade A+ is equivalent to PVC/A according to IEC 60502-1, ensuring compliance with established quality and safety requirements.

This grade is ideal for manufacturers seeking a high-performance, visually appealing, and standard-compliant cable sheathing solution that balances mechanical strength with reduced material density.

Product Grade: Product Grade: |  Color: Color: |

|---|---|

| 125CCZ 001 | Colorless |

| 125CCZP 001 | Black |

| 125CCZP2 001 | Red |

| 125CCZP3 001 | Yellow |

| 125CCZP4 001 | Green |

| 125CCZP5 001 | Brown |

This grade is engineered with an optimal specific gravity that fully complies with the requirements of PVC/D IEC 60227 standards. In addition to meeting these strict standards, Grade A provides a superior surface gloss, ensuring both technical performance and an enhanced visual finish for the final product.

Its balanced formulation offers excellent processability, mechanical strength, and durability, making it a reliable choice for high-quality flexible cable sheathing. The glossy surface finish not only improves the aesthetic appearance of the cables but also reflects the precision and stability of the compound during production.

**** A comparable grade with the same quality and specific gravity is available under the code 125CCZ 014, offering manufacturers a dependable alternative for consistent production results.

Product Grade: Product Grade: |  Color: Color: |

|---|---|

| 125CCZ 008 | Colorless |

| 125CCZP 005 | Black |

| 125CCZP1 007 | Blue |

| 125CCZP2 007 | Red |

| 125CCZP3 007 | Yellow |

| 125CCZP4 005 | Green |

| 125CCZP5 005 | Brown |

| 125CCZP6 001 | Gray |

Among the different grades of flexible cable sheathing compounds that comply with IEC 60227 standards, Grade B stands out as the most economical option. This grade is characterized by its highest specific gravity, which is achieved through optimized formulation and careful selection of raw materials.

While it offers a cost-effective solution, it still maintains compliance with the essential mechanical and electrical requirements defined by the standard, making it suitable for applications where affordability is prioritized without compromising on basic performance.

Grade B is therefore widely used in general-purpose flexible cables, providing manufacturers with an option that balances standard compliance, acceptable durability, and reduced production costs, making it an attractive choice for price-sensitive markets.

Product Grade: Product Grade: |  Color: Color: |

|---|---|

| 125CCZP 009 | Black |

| 125CCZ 016 | Colorless |

| 125CCZP6 002 | Gray |

| 125CCZP1 011 | Blue |

| 125CCZP2 012 | Red |

| 125CCZP3 010 | Yellow |

| 125CCZP4 008 | Green |

| 125CCZP5 008 | Brown |

PVC Sheathing

PVC compound type ST2 is a specially engineered formulation developed for high-temperature cable insulation and sheathing, supporting a continuous working temperature of up to 90 °C. It incorporates advanced heat stabilizers, high-quality PVC resin, and precise lubricant systems to ensure reliable performance under demanding thermal and mechanical conditions.

The compound provides excellent resistance to heat, moisture while maintaining flexibility and mechanical strength over time. This makes it an ideal material for automotive, industrial, and high-temperature electrical cables.

Its smooth and glossy finish, combined with color stability and ease of processing during extrusion, ensures a consistent, durable, and professional final product.

Product Grade: Product Grade: |  Color: Color: |

|---|---|

| 127CCZP 004 | Black |

This product is designed for use as sheathing for flexible cables (stranded cables) with a voltage rating of 450/750 V. It is formulated with high-quality additives, including strong stabilizers and plasticizers, to ensure optimal performance.

According to the PVC/ST5 IEC 60227 standard, this product is required to demonstrate mechanical strength of 10.5 MPa and a minimum elongation of 150%.

One of the distinctive features of Khorram Plastic’s insulating compounds is the high gloss of the final product surface, which enhances both appearance and perceived quality. This grade also exhibits the lowest specific gravity while delivering the highest mechanical properties, making it an excellent choice for manufacturers seeking both performance and material efficiency.

Product Grade: Product Grade: |  Color: Color: |

|---|---|

| 116CCZP1 001 | Black |

| 116CCZT1 | White |

This product is designed for use as sheathing for flexible cables (stranded cables) with a voltage rating of 450/750 V. It is formulated with high-quality additives, including strong stabilizers and plasticizers, to ensure optimal performance.

In accordance with the standard PVC/ST5 IEC 60227, this product is required to demonstrate mechanical strength of 10.5 MPa and a minimum elongation of 220%.

One of the distinctive features of Khorram Plastic’s insulating compounds is the high gloss of the final product surface, which enhances both aesthetic appeal and perceived quality. Despite offering excellent mechanical properties and superior surface gloss, this grade remains a cost-effective solution, providing manufacturers with high-quality performance at a competitive price.

Product Grade: Product Grade: |  Color: Color: |

|---|---|

| 116CCZT 005 | White |

| 116CCZP1 007 | Black |

| 116CCZP1 006 | Black |

| 116CCZT 009 | White |

| 116CCZP 001 | Black |

| 116CCZ 004 | Colorless |

Grade B is a calcium-zinc based compound (environmentally friendly) recommended for flexible cable sheathing applications, particularly for use in extruders with L/D ratios of 22–24.

Products manufactured with this grade exhibit high gloss and a smooth surface finish, ensuring both visual appeal and functional quality.

This compound is produced in compliance with the relevant industry standards, including IEC 60227: PVC ST5 and BS 6746: TM2, providing manufacturers with a reliable, standard-compliant material suitable for high-quality cable production.

Product Grade: Product Grade: |  Color: Color: |

|---|---|

| 116CCZT1 001 | White |

| 116CCZP1 013 | Black |

Filler

Fillers are used in cable construction to create a more uniform, round, and smooth cable structure, while also filling the empty spaces between conductors. They contribute to a cleaner cable appearance, increase overall flexibility, protect the insulation and sheath, and facilitate the manufacturing process. Cable fillers are commonly produced from PVC due to its flexibility, durability, and ease of processing.

By utilizing modern technology, advanced technical expertise, and strict compliance with relevant industry standards, Khorram Plastic Tehran Company has become one of the pioneers and leading producers of PVC cable fillers in Iran.

Heavy Filler: This product has the highest specific gravity among fillers and can provide economic advantages to the final wire and cable products.

The compound is calcium-zinc based (environmentally friendly) and is recommended for filler applications in various types of cables. Products manufactured with this grade exhibit high gloss and a smooth surface finish, ensuring both excellent visual appeal and consistent quality.

Product Grade: Product Grade: |  Color: Color: |

|---|---|

| 107CCZ1 | Colorless |

| 107CCZP1 | Black |

Light Filler: This product demonstrates remarkable mechanical properties compared to other fillers.

The compound is calcium-zinc based (environmentally friendly) and is recommended for filler applications in various types of cables. Products manufactured with this grade feature high gloss and a smooth surface finish, ensuring both excellent visual appeal and consistent quality.

Product Grade: Product Grade: |  Color: Color: |

|---|---|

| 131CCZP1 | Black |

| 131CCZ1 | Colorless |